Our Achievements

Stand out for our passion for meeting every technical challenge through constant innovation

Building Lasting Relationships

Check out our many success stories below!

A chassis part is delivered to the edge of the production line. This part must be lifted, rotated and then installed on the chassis on the production line. Close collaboration with the production team has allowed us to offer an innovative design that limits user errors to a minimum.

Complexity

- Secure holding of the part in vertical and horizontal positions

- Evaluate sticking points and possible operator error

- Lifting point limited by the aesthetics of the part

- No pneumatic or electric

Final requirement

- Design and certification of lifting equipment

- Complete risk analysis

- Complete user manual

- Lifting ratio 125%

Partial chassis manipulator

In order to perform a tension adjustment, a part must be lifted. This mandate consists of analyzing and certifying the lifting capacity of a maximum load of 200 lbs from a mobile equipment on a production line. We followed the development of this design to influence and advise the sizing of the critical sections of this lifting equipment.

Complexity

- Height adjustable

- 3 different loading cases

Final requirement

- Certification of lifting equipment

Structural analysis

Regular access to this machine caused frequent stoppages, since lockout was required even for simple routine cleanings (1 to 2 times per shift). In order to increase employee efficiency while still complying with machine safety rules and standards, the client decided to modify access to the equipment.

Complexity

- Autonomous maintenance of the staircase in the raised position

- Assessment of pinch points and potential operator errors

- Noise reduction during upward and downward movements

- Design without the use of pneumatics or electricity

- Compliance with the robustness and standard dimensions of a staircase

Final requirements

- On-site measurements

- Design and integration of electrotechnical components

- Supervision of manufacturing and installation

- Symmetrical solution adapted to both sides of the machine

Custom staircase

This project consists of being a clamping station whose sequence of clamping is very important. The equipment allows to read the exact position of each of the intelligent clamping tools with the help of encoders and a PLC.

Complexity

- Maximum use of 12 in. on the floor

- Return of tools to a minimum height of 7 feet

- Creation of a ball joint system

- Integration of 3 position encoders

- Find and integrate a reaction bar system with balance

- A clean environment (clean room ISO Class 8)

Final requirement

- Complete mechanical design

- Mechanical certification of the equipment

- Follow-up with the client responsible for the project and the electrical engineers

- Integration of smart tools

- Participation in risk analysis

- Complete user manual

Localized clamping equipment

This project involves creating a logistics cart that improves ergonomics. The parts, which are approximately 36 inches long by 24 inches wide, weigh between 12 and 25 lbs. Previously, these parts were installed vertically in a transport cart. With this cart, the parts are horizontal and limit the movements that the employee must make with the part.

Complexity

- Minimum of four large pieces

- Allow a sequencing order

- 80% aesthetic part

- Hold the part during internal transport

Final requirement

- Complete mechanical design

- Mechanical certification of the equipment

Ergonomic transport trolley

To ensure reliable assemblies, it is essential to use quality bolted joints in our customers' products. Thanks to intelligent tooling equipped with high-precision sensors, it is possible to analyze their behavior in detail.

For example, the images below show an M8 bolt of grade 8.8, whose standard tightening torque is normally 30 Nm. From the graph, we observe that the threads of the bolt start to deform from 30.20 Nm.

This type of analysis makes it possible to evaluate the behavior of critical assemblies and better manage the risks associated with inadequate tightening.

Bolted Joint Analysis

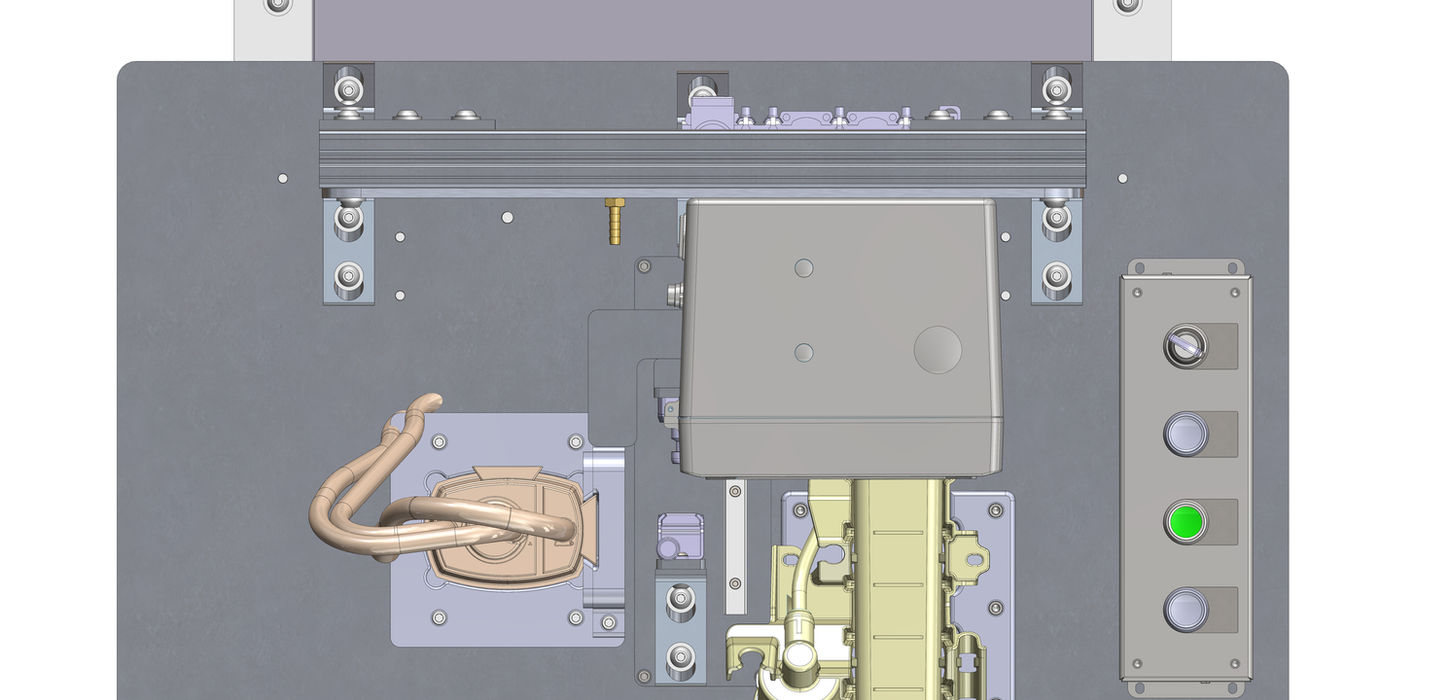

This project was to perform an air leak test on several different systems. This jig is a table on wheels, adjustable in height for ergonomics that includes the electrical panel, the activation buttons as well as the leak test machine.

Complexity

- Three different models to test

- Ergonomics

- Blocking of parts

Final requirement

- 3D and 2D design

Anti-error leak test template

A manual press that is used by a mechanic always involves a certain risk of use. This jig allows the depressing of a sprocket system in a safe manner.

Complexity

- 7 different models to depress

- Ergonomics

- Blocking of parts

- Adapt to current hand press

Final requirement

- 3D and 2D design

Hand press tools

Unfortunately, no information other than images can be displayed. This project requires greater robustness as well as better accuracy compared to the system previously used by the client.

Complexity

- Accuracy to 6 ft (1.82m)

Final requirement

- 3D and 2D design

Confidential

This project consisted of recovering an old hydraulic press to change its vocation as well as updating it to comply with current safety standards. The electronic update was also carried out with the help of other suppliers of the client such as the addition of hydraulic and pneumatic safety valves, the addition of an operator interface screen (HMI) as well as a category 4 PLC. Compared to a similar project, the recovery of a hydraulic and mechanical system saved more than $50,000 compared to the complete creation of a press with brains.

Complexity

- Five different shock absorbers to assemble

- Determine and manage machine modifications

- Use of hydraulics for medium-precision application

- Added sensors for different operating requirements

Final requirement

- Complete mechanical design

- Mechanical certification of the equipment

- Follow-up with electrical engineers/programmers

- Complete risk analysis

- Complete user manual

Hydraulic press update

Unfortunately, no information other than the images can be displayed. This project requires the part to be held by its own weight since the location where it is placed is extremely limited. The weight of the part is relatively light (less than 20 pounds). The ergonomic analysis of the workstation required a manipulator since the weight was repeatedly above the shoulders.

Complexity

- Very limited room storage space

- No retention possible on the part (friction only)

Final requirement

- 3D and 2D design